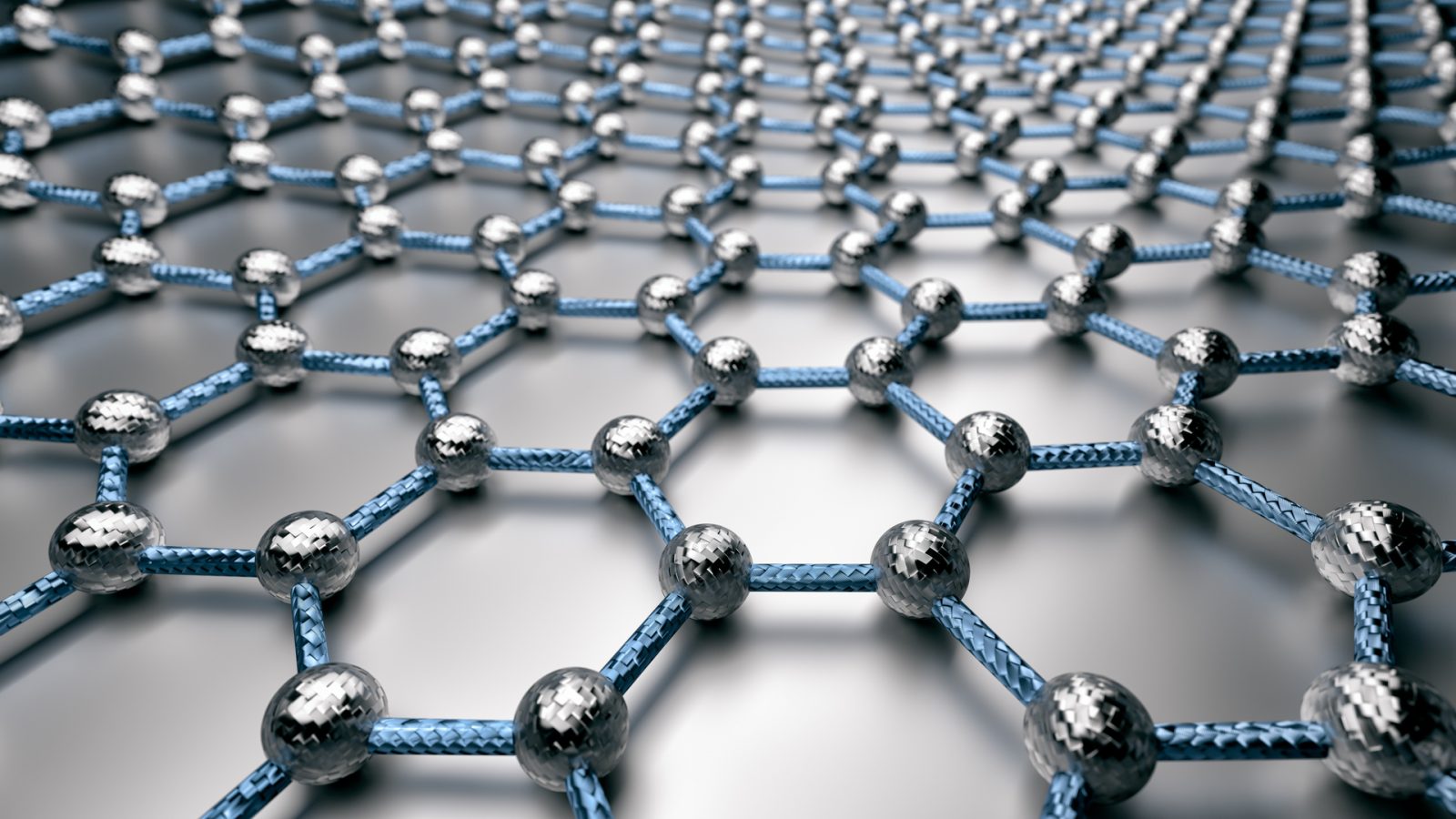

One sheet of carbon atoms organized in a triangular combination of two dimensions, graphene, has generated a lot of interest. Excellent thermal and electrical conductivity, it is strong and very light. Because of its numerous properties, graphene is an ideal material for coatings among other applications. Graphene coatings are finding increasing use to extend the life and performance of numerous surfaces, from consumer electronics to industrial equipment.

Why Coat with Graphene?

A robust, protective layer provided by graphene coating in Bangalore can significantly extend the life of the coated item. Suitable for use in severe environments, this coating resists wear, corrosion, and chemical damage. Moreover, its outstanding electrical and thermal conductivity makes it useful in heat-sensitive applications and electronics.

A coating of graphene in Bangalore

Modern industry and technology are concentrated in Bangalore, sometimes known as the Silicon Valley of India. This city is developing and implementing graphene coatings because of its focus on cutting-edge technologies. Its fast-growing industries, including electronics and cars, are increasing demand for high-performance coatings. The graphene coating services in Bangalore meet this demand by offering state-of-the-art solutions that increase the effectiveness and durability of various products.

Bangalore Graphene Coating Applications

Automotive Sector

Bangalore’s automobile sector benefits greatly from graphene coating. Graphene coating in Bangalore can be applied to the exterior, engine parts, and interior surfaces of a car. Graphene coating bangalore offers superior heat, corrosion, and scratch resistance, keeping the car looking good and extending its life. Additionally, graphene’s lightweight characteristics can result in better fuel economy.

Industry of Electronics and Electrical

Graphene coatings are used to increase the lifetime and performance of electronics and electrical industry goods. Bangalore is a major electronics production hub, so graphene coatings are extensively employed in consumer electronics like tablets and cell phones. The high electrical conductivity of graphene ensures better performance of electronic components, and its protective properties prevent it from thermal and environmental degradation.

Infrastructure and Construction

Bangalore’s building and infrastructure industries are also seeing a big influence from graphene coatings. Building materials like steel and concrete can have these coatings applied to them to offer better defense against corrosion, weathering, and other environmental pressures. Longer-lasting buildings with less maintenance expenses follow from this. By improving the thermal insulating qualities, graphene coatings can also help buildings become more energy efficient.

Aerospace Sector

Materials needed by the aircraft sector must be lightweight and resistant to harsh environments. Perfect for this are graphene coatings. These coatings are applied to shield aircraft components against corrosion, wear, and heat damage in Bangalore, a hub for aerospace research and manufacture. This increases the effectiveness and general safety of the aircraft in addition to prolonging the life of the parts.

Benefits of Bangalore Graphene Coating Services Utilization

Durability and Prolonged Life

The remarkable endurance of graphene coatings is well-known. Surfaces are shielded against physical harm, chemical deterioration, and environmental wear by their strong barrier. Longer-lasting goods and structures result from this higher durability, which is especially helpful in industrial applications.

Enhancement of Performance

High electrical and thermal conductivity, among other special characteristics of graphene, improve coated products’ performance. Better conductivity and heat dissipation in electronics translates into more dependable and efficient equipment. Better thermal management in industrial applications might result in higher productivity and lower energy use.

Economy of Cost

Even if using graphene coatings may be more expensive initially than using conventional coatings, the advantages over time exceed these expenses. Over time, the longer lifespan of coated products lowers the need for routine maintenance and replacements, which results in large cost savings.

Advantages to the Environment

Coatings using graphene can support environmental sustainability. Their robustness and capacity to protect lower the need for replacements and repairs, which cuts down on waste. Furthermore, lowering carbon emissions and energy consumption can result from their application in improving the energy efficiency of cars and buildings.

Bangalore’s Graphene Coating Future

Bangalore’s graphene coating future seems bright. Even more creative uses and enhanced performance of graphene coatings are to be expected as research and development in this area progress. Bangalore’s emphasis on technology innovation and expanding industrial base make it an ideal location for the development and use of graphene coating technologies.

Scientific Developments and Novelties in Graphene Coating

The necessity for ongoing invention and improvements in application methods rises along with the demand for graphene coatings. Bangalore-based engineers and researchers are investigating fresh approaches to improve the quality of graphene coverings even further. Among these is enhancing the uniformity and thickness control during the application process, which may lead to even more robust and effective coats.

Diverse Industries Customized Solutions

Offering customized solutions catered to the particular requirements of various sectors is one of the main benefits of graphene coating services in Bangalore. For instance, whereas the electronics business could concentrate on improving electrical conductivity, the car industry would need coatings that are more resistant to heat and abrasion. Through an awareness of the particular needs of every industry, service providers may provide customized graphene coatings that optimize durability and performance.

Integrating with New Technologies

Another fascinating aspect is the combination of graphene coverings with other developing technologies. For example, multifunctional coatings having hitherto unheard-of qualities can be produced by fusing graphene with nanotechnology or sophisticated composites. These developments could create new opportunities in domains like biomedical engineering, where coatings could serve both therapeutic and protective purposes.

Green manufacturing and sustainability

Growing focus is being placed on sustainability and environmentally friendly production methods in Bangalore. Considering that graphene coatings may help many businesses lessen their environmental effect, they fit in nicely with these objectives. Longer-lasting goods made possible by the use of graphene coatings can save waste and the need for frequent replacements. Furthermore improving the sustainability of graphene coatings is the fact that developments in the manufacture of graphene itself are making the process more ecologically friendly.

Conclusion

Many industries may benefit from graphene coating services in Bangalore in many ways. The applications are many and important; they include extending the life and energy economy of infrastructure and buildings as well as improving the efficiency and robustness of electrical and car parts. Bangalore is the ideal location to research and produce graphene coating technologies because of its stellar reputation as a technological hub and the incredible properties of graphene. Graphene coatings will have a big impact on many industries in Bangalore and beyond as people will always require high-performance, long-lasting, and competitively cost solutions.